FLUORBONDTM

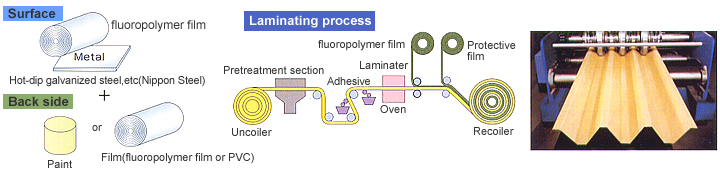

High quality galvanized steel, stainless steel (both made by Nippon Steel ), and Aluminum, laminated with fluoropolymer film.

FluorbondTM is exceptionally resistant to weather, corrosive environment, chemical, solvent, stain and abrasion by having fluoropolymer film on its surface.

1. Production process and forming of FluorbondTM

2. Typical structure

|

3. Strong feature

1. Superior long time durability with less color fading

(Superior resistant to weather, corrosive environment and stain)

Because of its fluoropolymer film surface, FluorbondTM has strong resistance to sunlight, oxidization and corrosion, and it will be hardly attacked by most of the solvent, alkali and corrosive materials. This is why FluorbondTM is widely adopted at seaside industrial areas. Such experiences show its durability. Besides, even if FluorbondTM surface is stained by something, the stain can be easily removed by using solvent or strong detergent.

2.Impressive construction with beautiful color selection

Low gloss surface finishing softens the distortion of appearance, which is caused by unavoidable thermal expansion of exterior panel.

3. Excellent formability

FluorbondTM can be punched-out, bent, roll-formed and deep-pressed because it has excellent adhesion between fluoropolymer film and substrates.

4.SuperDyma®, which is excellent durable metal, can be selected as a substrates material of FluorbondTM

By using SuperDyma® substrates, you can be secured 15 times high corrosion resistance (salt spray test) of hot-dip galvanized steel although the zinc thickness is the same between them. In other words, you can conduct “the cost down” by decreasing of zinc thickness. Some of our customers adopted Highly Corrosion-resistant Coated Steel Sheets instead of stainless steel and /or aluminum substrates.

*”SuperDyma®” is a product of Nippon Steel Corporation, with a high corrosion-resistant zinc coated steel sheet.

4.Property examples

| (1) T bend test (1T) | (2) Salt spray test result after 2000h at T bend (0T) | ||

|

|

|

|

5.Application examples

Noise barrier walls (exterior) |

Thermal power plant |

Drain board of roof skylight  |

Exterior walls of station of Japanese High Speed train |

0ffice exterior walls  |

Train shed  |

Seaside warehouse (22 years) |

Edge of warehouse roofing(22 years)  |

|